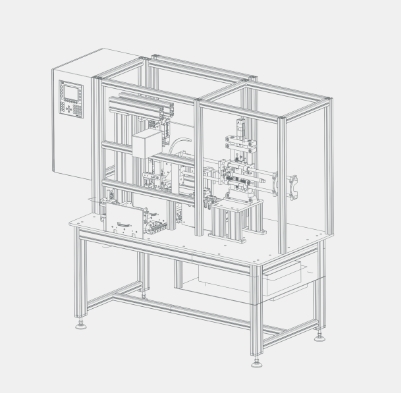

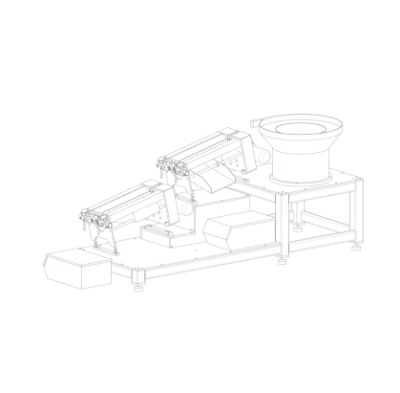

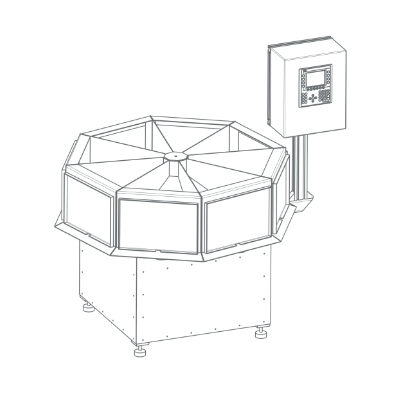

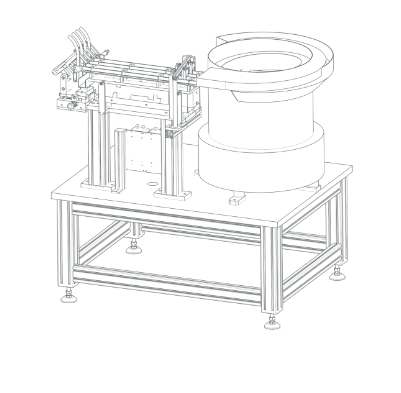

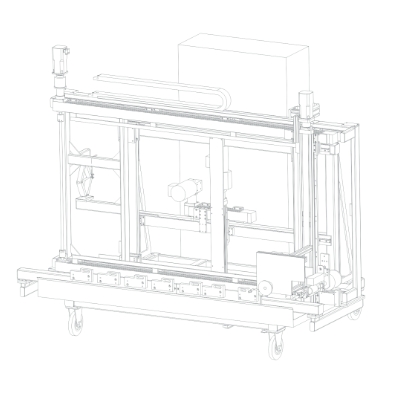

OUR STRENGTH - EVERYTHING FROM A SINGLE SOURCE

In order to integrate assembly systems quickly and reliably into existing production processes at your site, we take all customer-specific requirements into account, from planning and assembly to commissioning. We also support our customers in the technical and economic decision for the appropriate level of automation: automated, semi-automated or manual.

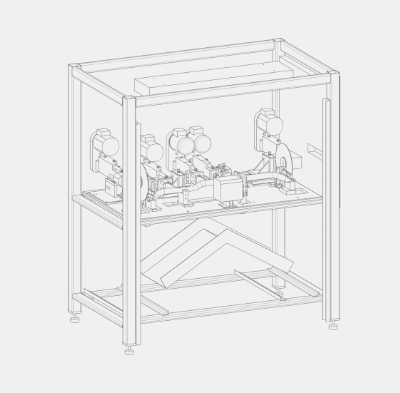

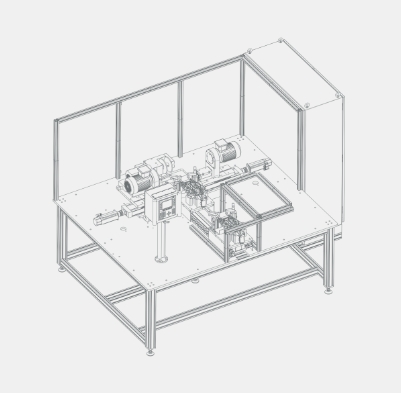

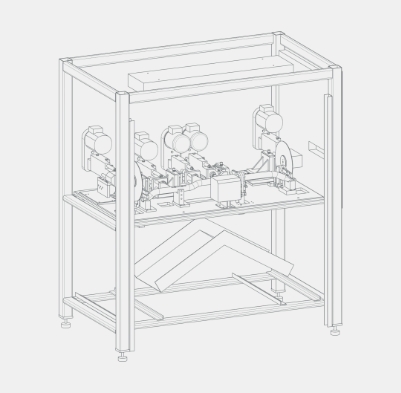

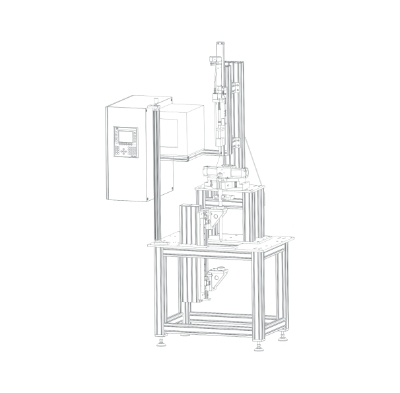

WE MASTER EVERY TASK

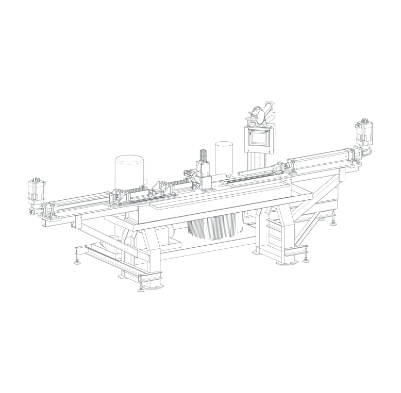

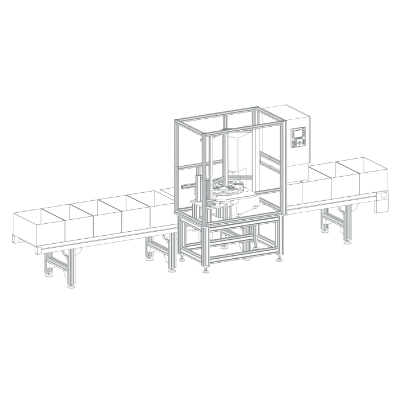

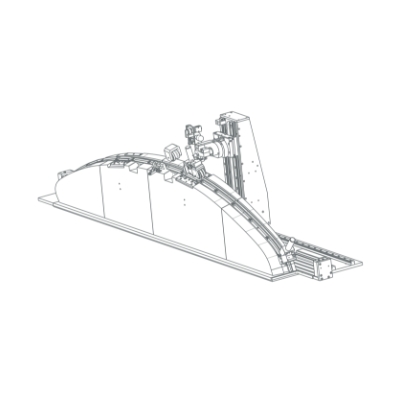

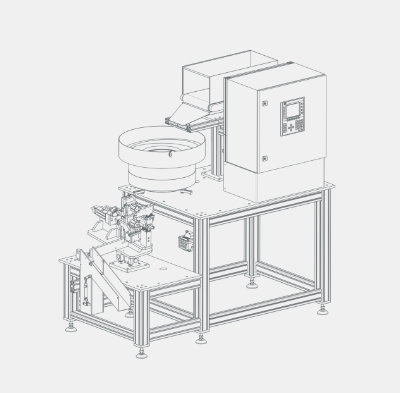

- machining

- assemble

- testing

- distributing

- Rolling

- Specialized tasks

KNOW-HOW IN SPECIAL MACHINE CONSTRUCTION -

RELIABLE AND VERSATILE

Since the company was founded, customers have relied on our experience in the development of individual solutions.

Whether simple feeding technology or complex process integration - we create special-purpose machines for a wide range of industries and applications.